Jamison Industrial Doors

It’s not just the door. It’s what’s behind it.

Since 1906, Jamison Door Company has pioneered the cold storage door industry in unsurpassed product quality, workmanship, and service. Whether it swings, rolls, slides or uses a curtain of air, a Jamison door is built for performance. Jamison’s unwavering standards have made it the most sought-after door brand in the industry.

When you buy Jamison, you buy more than a door. You buy the expertise and experience of a company with demonstrated leadership in the design and manufacture of doors for all types of environments. For applications of any size or complexity, we offer a wide range of Jamison solutions.

Why Customers Choose Jamison

- Each door is engineered for your application

- Hand-constructed framing and quality hardware for a longer door life

- Special focus on gasket materials, design, and ease of installation

- Patented low-friction Diamond-Trac

- System making even large doors easy to move

- 5-year limited warranty on all Mark IV Doors and Plyfoam Doors

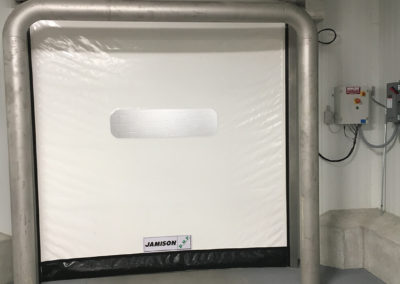

HIGH-SPEED FABRIC & STEEL ROLLUP DOORS

Jamison has partnered with the fastest growing performance fabric and steel door manufacturer in the world, BMP, to manufacture their broad range of industrial, retail, pharmaceutical, and food doors. Receive BMP’s innovative and dependable designs delivered by Jamison’s world-class engineering, manufacturing, and customer service.

Features and Benefits

- Extremely fast, extremely safe, self-repairing

- Fast with standard opening speeds up to 100” a second for most sizes

- Safe with a soft bottom edge as standard, unlike hard rigid bottom edges of most manufacturers

- Automatically resets for most hits due to the track reset notch positioned at the top of the opening

- Use of materials not requiring lubricated tracks

- Injection-molded teeth that stay on the curtain unlike mechanically fastened teeth

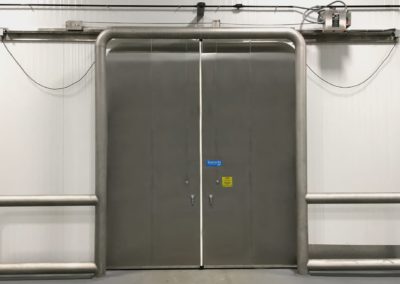

COLD STORAGE DOORS

Manufacturing state-of-the-art solutions to unique cooler and freezer applications has been Jamison’s passion for more than 110 years. Whether they are sliding, swinging, bi-folding or overhead, or hittable, clear panel, stainless steel or molded plastic, Jamison doors are extremely versatile with design configurations for any type of cold storage environment. Jamison is one of the last manufacturers to still design and build its own power operators, and the Powertron Operator is the most popular operator in the history of cold storage doors. Jamison Cold Storage Doors are chosen most often throughout the food processing, food service, and temperature-controlled storage/distribution industries.

Features and Benefits

- Power-operated or manually-operated

- The most popular power operator

- Superior sealing ability of our Diamond-Trac® Roller System

- Padlockable safety release latches and optional kick plates for added protection of swing doors

- 5-year limited warranty

SWING DOORS

In 1958, Jamison introduced their first fiberglass door with the manufacture of the Jamolite product line. With 60+ years of experience creating and perfecting fiberglass doors, Jamison has introduced its subsidiary company, Jamotuf®, LLC, specializing in 1-3/4” thick fiberglass doors with fiberglass frame options. The smooth gloss gelcoat surface is exceptionally clean, non-porous, and non-absorptive. Jamotuf doors are durable, low-maintenance, and have a lifetime corrosion warranty.

“Tuf” and beautiful — the Jamotuf product line is the perfect combination of form and function.

Features and Benefits

- Monolithic molded construction for a true seamless impermeable outer shell

- Molecular crosslinking of all six sides of the door ensures integrity of the seamless design

- Outer shell is press-molded to composite core materials for a variety of applications and designs

- A wide range of hardware preps or Grade 1 hardware accessories

- Installation of factory-supplied finish hardware available

Case Study: Jones Dairy Farm

Project Overview

Jones Dairy Farm is a 6th generation family-owned and operated company located in Fort Atkinson, Wisconsin. For more than 130 years, Jones has been using real, natural ingredients, original recipes, and time-honored traditions to create unique and timeless products. Jones is known for producing All Natural Sausage, Naturally Smoked Hams, and Dry-Aged Bacon products, all free of artificial preservatives, fillers, and MSG.

In order to increase production capabilities, Jones Dairy Farm underwent an expansion and renovation of the former McCain Foods Inc. plant. This included a 68,183 sq-ft. addition to the existing processing plant, resulting in a 306,263 sq-ft. total facility. The expansion consisted of a new process area, refrigerated truck dock, employee area mezzanine, and parking and site improvements.

Delta T Construction was chosen as the cold storage contractor for this expansion by ESI Group USA. They chose to use Jamison Cold Storage and Jamison BMP High Speed Fabric Rollup doors in their construction.

Stats and Scope

Jamison Cold Storage Doors

- (17) Mark IV Horizontal Single

- (2) Mark IV Horizontal Bi-Parting

- (1) Mark IV Vertical(8) Plyfoam II

BMP High Speed Fabric and Rollup Doors

- (4) DynamicRoll Doors

Favorite Project Features

- It is quite a statement having all doors in stainless steel. The non-corrosive stainless hardware is extremely heavy-duty.

- Jamison’s Dynamicroll BMP doors included stainless steel side frames and hood with an FDA approved fabric material. Their simple design makes them easy to operate and maintain. Also, easily cleaned!

- The doors are not just aesthetically pleasing, but provide great functionality in an area of harsh chemical washdown.

“This was an area of harsh chemical washdown and I am very pleased that we were able to supply the complete door package at the corrosive-resistant degree Jones Dairy Farm requested.”

Case Study: Kraft Heinz

Project Overview

When Kraft Foods Group and H.J. Heinz Company merged in 2015, the resulting Kraft Heinz Company became what is the third-largest food and beverage company in North America and the fifth-largest food and beverage company in the world.

In order to grow its brands and enhance its capacity for innovation and product quality over the last few years, more than $1.5 billion was invested in global manufacturing facilities. $225 million of this investment went into the new 382,000 sq-ft. facility in Davenport, IA. This new facility is located across 70 acres and produces a range of Oscar Mayer deli meats. Total processing capacity includes 2.8 million pounds per week.

The Davenport facility was completed in several phases. Gray Construction was initially brought in to design and build the facility, and Delta T Construction completed the first phase of cold storage construction installing one of Jamison’s largest orders to date. Sprinkmann Sons Corporation, Barron Equipment, and Total Construction Solutions were contracted for expansion phases.

Stats and Scope

Jamison Cold Storage Doors

- (91) Mark IV Horizontal Single

- (30) Plyfoam II

- (10) Jamolite II

Jamotuf Fiberglass Architectural Style Doors

- (169) Jamotuf Doors

- (3) Jamoclean

Favorite Project Features

- This was an area of heavy washdown that required a unique set of Jamison products.

- A special washdown package was provided, including fiberglass doors with stainless hardware.

- The ease of installation was critical due to the tight schedule Kraft needed to adhere to. Over 200 swing doors shipped pre-hung with the hardware already attached creating a quick, easy and hassle-free door installation.

“We were able to ship and install 303 doors on a rather compressed schedule in order for Kraft to meet their important deadlines. Quality products at that quantity and speed is very significant.”

Contact Us

Let Us Contact You with a Solution

Please fill out the form below and one of our experts will reach out to you.

About KMK Sales

At KMK Sales, we represent the top manufacturers in the food processing industry when it comes to industrial doors, air doors, insulation, and innovative products like Vapor Armor.

Whether you are in the beginning stages of engineering a new interior or exterior, working to make an existing space more functional, or looking for an effective solution to an issue you are facing, we know everything there is to know about cold storage products and have the wealth of knowledge and hands-on experience you are looking for to make a decision.

Reach out to speak with an expert today on which products are right for you and your application. Above all else, our goal is to listen to and understand your needs and offer the right solutions.